WESTBURY ENVIRONMENTAL LIMITED BLOG

Wood and POPs waste: Have you taken action?

There has been a lot of talk recently about the withdrawal of RPS250, concerning hazardous waste wood, and the restrictions concerning wastes that potentially contain Persistent Organic Pollutants (POPs) including domestic seating and cables. I have certainly put time into reading the guidance published on .gov.uk and by the Wood Recyclers Association. However, talking to operators of waste transfer stations there seems to be a good amount of confusion as to what they should be doing about this, how to document it, record and train staff to ensure they remain compliant.

My approach to providing advice in such cases is to break it down and keep it as simple as possible. Permitted waste transfer stations are required to have a written Environmental Management System so that, in my opinion, is where to start. Including relevant information into a number of procedures within your EMS is key to implementing the required changes. I have included a short list below to explain what I mean:

- Pre-acceptance Procedure - Include information in this procedure to ensure that you are seeking the correct information from your customers about waste wood, domestic seating and cables before the waste is sent to you.

- Waste Acceptance Procedure - Include information in this procedure concerning the identification of waste items that may not be acceptable on the site. Be sure to include a list of acceptable waste codes in this procedure for reference.

- Waste Rejection Procedure - Include information in this procedure so that staff know what to do if, for example, waste arrives on the site that is suspected of having been described / classified incorrectly.

- Waste Classification Procedure - Include information in this procedure on the lab test suites that should be used if waste sampling, testing and classification is required to evidence if a waste is hazardous or non hazardous.

- Waste Storage Procedure - Include information in this procedure to inform staff on the particular storage requirements for these waste types.

- Waste Treatment Procedure - Include information in this procedure to describe how this waste is to be treated including additional emission abatement systems required. For example, extraction hood over shredders for POPs waste.

- Waste Removal from Site - Include information in this procedure to ensure that particular wastes are sent to appropriate disposal facilities. With the aforementioned wastes it is likely that this would be an IED chapter 4 permitted incinerator.

The above is only a suggestion but I feel that this approach has many advantages over creating separate procedures for the requirements of the different waste types, for example – having a waste wood procedure and a POPs waste procedure.

And then the most important thing will be to train your staff on the changes that have been made to the EMS Procedures.

Change is the only thing in life that we can be certain of, and that doubly applies to the regulation of waste. I feel that having a consistent approach to dealing with changes can greatly reduce the stress and problems that change can cause. Including information on the new requirements into your EMS, in a well-organized and thoughtful way, will help ensure compliance in an effective and efficient way.

30 November 2023

There has been a lot of talk recently about the withdrawal of RPS250, concerning hazardous waste wood, and the restrictions concerning wastes that potentially contai... Read more

Exemptions Review: Get ahead to save costs

I recently wrote about the proposed changes to Standard Rules Permits so it’s a logical next step to talk about proposed changes to the Exemptions from the need to obtain Environmental Permits.

Detailed information has been published about the proposed changes that are due to come into force in 2024. Essentially, some waste activities that are currently exempt from the need to obtain a permit will need a permit, to be undertaken.

A quick search on the internet will provide lots of the details about the proposed changes so I do not intend to cover these here. However, what I do want to cover is what action you should take to ensure that any changes are as painless as possible. I have listed below a number of suggestions to help you:

- Review your current registered exemptions – if you are not sure what you have registered then look on the Exemption Public Register on the environmental regulator’s website.

- Check each of your registered exemptions and consider if you still carry out the activity covered by that exemption.

- If no, then let it lapse or ask for it to be de-registered.

- If yes, then check the consultation document to see what the proposed changes are for that exemption.

- If you still wish to carry out an activity that will no longer be covered by an exemption, then you will need to apply for a permit or vary an existing permit. Either of these actions can be expensive in both time and costs.

- If you need to obtain a new permit, seek early advice so you can understand the costs and the process for both obtaining the permit and putting in place other requirements for permit compliance such as the environmental management System (EMS) and Technically Competent Manager (TCM).

If you need to vary an existing permit to include those previously exempt activities it’s likely you are familiar with the permitting process and have a TCM in place. Don’t forget that your EMS will need to be updated to include the additional activities and any new permit requirements. Depending on the proposed activities and what is already in your permit the application fee can vary significantly so take early advice.

There are lots of reasons why permits may need to be varied. Not least so, the forthcoming changes to the Standard Rules Permits. Therefore, I strongly advise looking at your permitting needs for the foreseeable future to ensure that a comprehensive permit variation application can be submitted that will include all the required changes. Making just one application could potentially save you thousands of pounds in application fees compared to multiple applications.

I understand that all the proposed changes to permits and exemptions can be daunting so to help you navigate these changes I am preparing a FREE 1-hour webinar to be held on Wednesday 27th September at 12pm. Further information will be released closer to the date. To register your place, simply click here to email us with the names and email addresses of those who wish to attend.

24 August 2023

I recently wrote about the proposed changes to Standard Rules Permits so it’s a logical next step to talk about proposed changes to the Exemptions from the need to o... Read more

Standard Rules Permits: Embracing change…or not?

The ‘change’ I am referring to here is the proposed change to some Standard Rules Permits that many waste sites will be operating under. This includes waste transfer stations, metal recycling facilities, household waste recycling centres, waste wood recyclers, construction / demolition waste recyclers and others.

At present the proposed changes are progressing through the consultation process and it is unknown when or what changes will be implemented. You can read the full consultation document on the .gov.uk website by searching for standard rules consultation no 25.

However, there are a few things we can be certain of:

- There are likely to be additional infrastructure requirements / changes to processes required for operators who remain operating under the new standard rules permits.

- There is likely to be a considerable number of operators who need to change their standard rules permit to a bespoke permit.

Will you embrace the change?? Likely not, as either of the two options above could be expensive. So, my advice is to take advice early and weigh up the options and costs. There is no need for any nasty surprises, your site and operations can be reviewed against the proposed changes. The consultation document proposes that once the changes are implemented operators will have three months to comply with the conditions of the new std rules permits or get bespoke permits. How this will work with the current long delays with permit applications being determined by the regulators is unknown!

For example, a construction / demolition waste recycler operating under a std rules permit 2010 no. 12 would need to undertake operations inside an enclosed building if there is a residential dwelling or workplace within 200m and have an impermeable surface with sealed drainage if the site is located within a groundwater Source Protection Zone two or three. Sites located in a Source Protection Zone one will not be able to operate under the new std rules permit.

Another example, non-hazardous waste handling and treatment under the new std. rules permits will have to be undertaken within an enclosed building. An enclosed building will have a minimal sized door so that precludes the typical three-sided building.

Applications for bespoke permits are likely to require management plans for dust, noise and/or odour. These will describe the mitigation measures appropriate for the site, operations and its surroundings to ensure that such emissions are controlled to prevent nuisance. The preparation and determination of these can add significant costs to the application along with the potential cost of installing equipment.

Please don’t hesitate to give us a call if you have questions regarding the proposed changes and what they mean for your site / operations. We can advise you how the location of your site could impact your options going forward.

21 July 2023

The ‘change’ I am referring to here is the proposed change to some Standard Rules Permits that many waste sites will be operating under. This includes waste transf... Read more

Sampling Plans for Trommel Fines

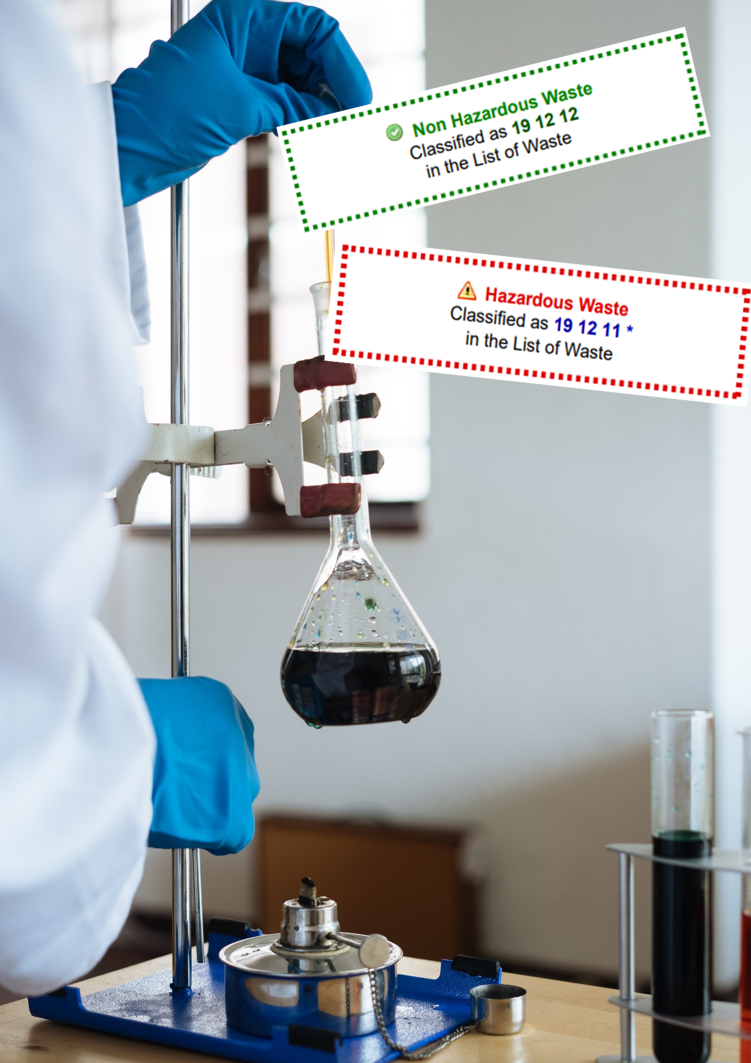

It has been just over a year since I wrote an article here about the action being taken by the Environment Agency (EA) to ensure that all trommel fines producers properly classify their trommel fines as hazardous or non-hazardous waste. The EA had sent out a letter that stated “only when a waste assessment, carried out in accordance with WM3 guidance, shows the waste does not display any hazardous properties, can the non-hazardous mirror waste codes be assigned (19 12 12)”. The need to classify waste in accordance with WM3 Waste Classification Technical Guidance is not new and actually applies to all waste regardless of its LOW code.

So, where are we one year on from this?

I am pleased to say that I am not seeing the EA taking a heavy-handed approach. Rather, they appear to be raising this as an issue on Compliance Assessment Report (CAR) forms and Waste Audit Report (WAR) forms subsequent to visits to waste facilities. Even when an operator has little to no evidence of hazardous waste assessments this is typically not resulting in non-compliance points being given on the CAR forms. However, they are generally asking for Sampling Plans to be submitted to them within a set timeframe.

Sampling plans need achieve two objectives:

- Provide information on the ‘Basic Characterisation of the trommel fines.

- Propose an appropriate on-going compliance sampling and testing frequency.

Let’s look at the basic characterisation step. This is an investigation that is carried out to determine the variability within the trommel fines in terms of hazardous properties. Typically, this can be achieved by sampling the trommel fines three to five times over the course of one day. Then repeating this for around three days in total, over several weeks. This should provide sufficient data to determine an on-going compliance sampling and testing frequency.

Ideally, spot samples taken from the flow of trommel fines should be collected in a clean container and then transported to the lab. Ask the lab to do a total content analysis on the sample. You may be used to asking for landfill WAC tests however, WAC tests do not provide the correct results on which a hazardous waste assessment can be carried out. Once you have your lab results a hazardous waste assessment needs to be completed to determine if the trommel fines display any hazardous properties. Review all the hazardous waste assessment results from your samples, you may need to do some statistical modelling of the results to determine the probability of the fines being non-hazardous/hazardous. The more certain you are that the trommel fines are non-hazardous, the less frequently you will need to do on-going compliance sampling.

Yes, I agree this does sound like a lot of work and I think the EA also appreciate that this will take time. However, as long as proposals to complete this work are submitted, from my experience, the EA are being reasonable about providing the necessary time.

So think about your sampling plan as having two stages or versions to it.

Sampling Plan Version 1 – contains proposals on the basic characterisation sampling regime, how you will take your samples, what you will test for and how you will assess the results. Submit this report in response to a request from the EA.

Sampling Plan Version 2 – contains the results and interpretation of the results from the basic characterisation investigation and a proposal of the frequency of on-going compliance sampling. Submit this to the EA when it is complete.

I have talked about Sampling Plans and Trommel fines in my webinars which have been recorded and are free to download here. If you can’t find the answer to your queries there, then please do not hesitate to call the office where one of my experienced consultants or I will be happy to help you.

30 November 2021

It has been just over a year since I wrote an article here about the action being taken by the Environment Agency (EA) to ensure that all trommel fines producers pro... Read more

Lab testing of waste: Knowing what to ask for

Do you send samples of waste for laboratory analysis? Do you understand the menu of options for analysis? Do you know what tests will give you the data you need? Do you understand the results that the lab provides? If you answered no to any of the above, then read on.

It is my experience that many samples of waste sent to laboratories for testing are resulting in inappropriate and often inadequate data being collected. Since this exercise is costly both in time and money it is important that this is done correctly.

Often, it can be a straightforward task, for example when you are testing a waste against a certain set of parameters, say on permit or other consent. You know what you need to test for and can compare your results with a list of limits. However, often this is not the case and you will need to decide what the lab should test for and then have an assessment carried out on the results. This is typically the case when testing waste, for example soil and trommel fines.

According to Waste Classification Technical Guidance WM3 all waste is classified as either hazardous or non-hazardous. To classify waste you need to know what hazardous properties the waste has and this will depend on the chemical substances that are present. There is no set list of chemicals to test for to be able to complete a robust hazardous waste assessment, this will always depend on what you expect the waste to contain.

All laboratories can provide a price for their ‘environmental suite’. This will typically include metals, non-metals, metalloids, total/speciated petroleum hydrocarbons (TPH), polyaromatic hydrocarbons (PAH) etc. While this is a good place to start, it may not be adequate in some instances.

In the course of my work as an Environmental Consultant I see a lot of laboratory data on which I am requested to carry out a hazardous waste assessment. I can assess whatever data I am provided but if the data set is inadequate so too will be the assessment. Here are some of the common mistakes I see:

- Just a spreadsheet of the lab results is not adequate. The actual laboratory report is required as evidence within the hazardous waste assessment report.

- Too few metals being reported on. It actually costs very little more to get results on a good long list of metals.

- Total petroleum hydrocarbons being reported for C5 to C35. This should be C6 to C40 to comply with WM3.

- Leachate test data only being provided (known as WAC tests). A hazardous waste assessment cannot be carried out on WAC data alone. WAC tests should only be carried out on waste samples that have already been classified a hazardous or non-hazardous and are going to landfill. WAC data is of little use for waste being sent for recycling, so don’t waste your money on this.

Since you get what you ask for from a lab give this some consideration, even talk to the lab staff. You will find they have a wealth of knowledge and are keen to help. If you send the lab a sample of say soil and ask for a WAC test, that is what they will do for you whether it is appropriate or not in your circumstances. To classify waste (assign the correct waste code) you need to obtain ‘total content analysis’ results – this means the lab tests for what is in the waste and not what leaches off it, as in the WAC test.

While variability of results between samples of waste causes problems so too does the variability of results from different labs. Not all laboratories will handle samples in the same way, and this can affect the reported results. Not all laboratories analyse for substances in the same way, and this can affect the reported results. This does not make the results wrong but means that details of sample handling (details of sample clean-up etc.) and how the test was completed does need to be accounted for in the assessment of the results.

Testing waste samples can often throw up some unexpected results. This can be due to interference from other substances in the waste affecting results. The most common example of this is with total petroleum hydrocarbons (TPH). Other organic materials in the sample can cause a false high result. However, if requested, the laboratory can perform a clean up technique on the sample to avoid this. The more accurate, lower TPH result may make the difference between the waste being classified as hazardous or not.

Laboratories can also perform tests that look for the presence of hazardous properties in waste. These can be especially useful when a waste has been assessed as having a hazardous property, but you have reasons to suspect that it does not. For example, flammability. The presence of flammable substances may cause a waste to be assessed as flammable and therefore hazardous. However, a flammability test may confirm it is not flammable, which may change the classification of the waste.

The enforcement of ‘classification of waste’ requirements by environmental regulators will undoubtedly lead to more sampling and testing of waste being carried out. The cost of this to waste operators is likely to be significant so this process needs to be as efficient and effective as possible.

To help waste site operators understand more about lab testing of waste, watch our free video - Testing Your Waste: What to Ask For here.

30 September 2021

Do you send samples of waste for laboratory analysis? Do you understand the menu of options for analysis? Do you know what tests will give you the data you need? D... Read more

Environment Agency Opens Definition of Waste Service

New guidance has been published (31st August 2021) by the Environment Agency (EA) with regard to “When a material is waste, is a by-product or meets ‘End of Waste’ Status”.

In this article I am going to focus on the subject of ‘End of Waste’ status as this is likely to be of interest to waste operators who wish to sell a recycled product – as a product and not waste. If the recycled product is not covered by a published Quality Protocol then there can be uncertainty over the waste status of the recycled material.

Going back a few years the EA had an end of waste panel to which applications could be made to get an opinion from the regulator as to whether they agreed that the end of waste test could be/ had been met. In my experience few applications submitted to the panel were approved, while many were left without conclusion. This panel closed and since then there has been no system in place to get a view on end of waste.

I have mentioned above the ‘end of waste’ test. Essentially, materials will be considered to have reached end of waste if:

- There is a clear use for the material.

- A market exists for that material.

- The material meets all the relevant technical requirements, standards and legislation.

- The material has no overall adverse effect on environmental or human health.

It’s good news that the EA have re-opened this service. So, let’s see what it looks like:

- Unlike the previous service, an application to the Definition of Waste Service has to be paid for. The cost is estimated by the EA based on a review of pre-application advice provided by the applicant.

- The application is made by completing a form that contains a significant amount of information however, the EA will provide initial free advice on what that information should include.

- The application requires a good amount of information on testing and assessment of the product.

- Ideally you will have selected a comparator product and completed a detailed comparison of the environmental impact of the use of your product and the comparator product. If there is no relevant comparator, then more assessment on the potential adverse environmental or human health impacts will have to be included in the application.

- Information on the market for the new product is required to be included in the application.

- This is not an exhaustive list but aims to give you a flavour of the application requirements.

Due to the obligation of public authorities to disclose information to the public there is no guarantee that the information you provide, in an end of waste application, will be kept confidential.

However, there is no absolute requirement to go through this application process since you are not obliged to get a view from a regulator on whether your material has reached end of waste. You can self-assess. As you can imagine, selling a product based on a self-assessment is subject to uncertainty that, should the Environment Agency check your self-assessment, they may disagree with the result. You may then be liable for unlawfully sending out waste without a waste transfer note and your customers may have used waste without necessary permits etc.

So, it’s not an easy process to navigate and there are no guarantees but at least now there is a way to get end of waste applications viewed and commented on by the regulator.

Westbury Environmental Limited have worked on a number of end of waste applications for our clients. Please do get in touch if you wish to discuss this subject further admin@westburyenv.co.uk. Whilst we have no scheduled webinar on this subject at present, it is likely that we will do soon. In the meantime, visit the Knowledge Centre on our website for recordings of previous webinars on typical challenges faced by waste operators.

29 September 2021

New guidance has been published (31st August 2021) by the Environment Agency (EA) with regard to “When a material is waste, is a by-product or meets ‘End of Waste’ Status”.

In ... Read more

How much wood can a woodchuck, chuck? …. Any amount as long as it is classified first!

The need to classify waste as either hazardous or non-hazardous is a requirement of waste regulation. How to classify waste is described in Technical Guidance WM3. Having said that let’s look at how the need to classify waste relates to waste wood.

Untreated wood can be assumed to be non-hazardous, while treated wood may be hazardous. Items such as telegraph poles and railway sleepers can be easily identified and assumed to be hazardous. However, some other treated wood items may not be visibly identifiable but may be hazardous. This issue is causing the wood recycling industry significant concerns.

The regulators and relevant trade associations have been discussing the impact of classification on wood recycling and disposal for several years. The need to implement classification to waste wood has been delayed by the Regulatory Position Statement (RPS) 207. This position statement has already been extended several times and is currently due to expire on 31st July 2021. Previous extensions were granted by the Environment Agency in response to requests from the Wood Recycling Association (WRA) to give them time to complete their sampling and investigation. When RPS 207 expires waste wood, that has not been classified, should be assumed to be hazardous. This will also apply to any waste wood that has been collected and stored on a site while the RPS was in force.

The WRA aims to identify those sources/types of waste wood that is likely to be hazardous. So far this has identified structural timbers, fence posts and decking as potentially hazardous. This means that on expiration of RPS 207 these items at least, would need to be segregated at collection and recycling facilities and any facility taking such items would need to be appropriately permitted to accept hazardous waste.

Should you have treated wood or mixed wood that needs to be classified you will need to follow WM3 guidance on sampling, analysis and assessment of the laboratory data to ensure that you obtain a robust assessment. The laboratory analysis of samples should include all substances that could be present and can incur significant costs. However, if you short cut this process by analysing for fewer substances it could mean that your assessment is not robust.

It is anticipated that there could be an increase in the number of EA inspections of wood recycling facilities when RPS 207 expires. Consider if you are prepared to evidence compliance with waste regulation. Ask yourself, do you:

- Have adequate procedures to implement waste classification requirements in your EMS?

- Appreciate the additional costs of sampling, analysing and haz waste assessing your waste wood?

- Have resources (in house or external) to implement these requirements?

We are specialist environmental consultants and carry out hazardous waste assessments for our clients in the waste industry. We also provide help and guidance on all aspects of permit compliance. Do get in touch if you need any help or advice.

08 July 2021

The need to classify waste as either hazardous or non-hazardous is a requirement of waste regulation. How to classify waste is described in Technical Guidance WM3. Having said that let’s loo... Read more

How much does an Environmental Permit cost?

Well that very much depends….. which side of the road are you on!

As an Environmental Consultant I get asked this question regularly and the only way I can answer it is to ask lots of questions….. and I mean lots of questions. I know that my clients find this a frustrating process, when they just want initial ballpark figures for budgeting, and I am unable to give them this without getting lots of information from them first.

You may think it’s pretty straight forward, after all the Environment Agency (EA) provide a Table of Fees and Charges which lists fees according to the type of activity you want to carry out. Perhaps an example would demonstrate the issues that are encountered.

I get an enquiry about obtaining a permit for a new construction / demolition recycling facility. Now this could be very straight forward or not! In this example the site is to be located on industrial land on the outskirts of a major city. Ideally, this operator would obtain a permit with the Standard Rules Set 2010 No.12. He could even do an online application himself, therefore avoiding consultant fees for preparing the permit application. However, on closer inspection of the location I find that it is located within an Air Quality Management Area (AQMA). This means that the site cannot have the Standard Rules permit, so a bespoke permit application will have to be made. The bespoke permit not only costs more to apply for but is also highly likely to require further assessments as part of the application. The table below shows how the comparison of costs stacks up!

| Item | Std Rules Permit 2010 no.12 | Bespoke Permit |

| Application Fee | £2,641 | £7,930 |

| Dust Management Plan | Not required | £1,241 |

| Noise Management Plan | Not required | £1,241 |

| Consultancy Fees | Not required | £6,000 to £12,000k* |

| Total | £2,641 | £16,412 to £22,412 |

- *Ball park estimate and dependent on the need for noise monitoring/assessment

- In this case, all the additional cost and assessment is required only due to the fact that the site is located within AQMA.

More complex waste operations, than the example above, have a greater number of potential additional costs which make it even harder to provide accurate cost estimates.

Once you have paid your fees and the EA have your application there is still the potential for further costs. Requests for further information and assessments from the EA while they determine your application are becoming more common.

I am generally an optimist, however when providing cost estimates for Environmental Permits I have to consider the worst case scenarios and ensure my clients understand what costs I can be certain of and those that may escalate.

If you are considering obtaining a new Environmental Permit or making changes to an existing permit don’t just ask the question ‘how much will it cost’ but also seek to understand the potential for costs to escalate.

We are specialist consultants in obtaining Environmental Permits for the waste industry. We also provide help and guidance on all aspects of permit compliance. Do get in touch if you need any help or advice.

31 May 2021

Well that very much depends….. which side of the road are you on!

As an Environmental Consultant I get asked this ... Read more

Your Dust Management Plan

I have noticed, over the last few years, an increased focus on the subject of dust emissions from waste facilities. Almost without exception, dust is raised as a significant concern in the development and operation of waste facilities.

I consider it almost impossible to handle waste without generating some dust however, if this dust could harm human health or cause a nuisance, then the regulators will be involved. Both planning authorities and environmental regulators will address this issue when applications for authorisations are determined and when regulating operational sites. Within applications there is commonly a requirement to provide a Dust Management Plan. Dust Management Plans may also be requested from operators when dust has been identified as causing a problem.

If you need to prepare or update a Dust Management Plan here are 10 useful points to help you.

1. Your Dust Management Plan should contain an assessment of the potential for the activities on your site to cause problems from dust emissions and demonstrate how adequate mitigation measures will be used.

2. Dust management procedures should then be written that implement the requirements of the Dust Management Plan. These would typically be implemented via your Environmental Management System.

3. Determine if there is a potential for the dust to reach levels or contain substances that could be significantly harmful to human health, for example asbestos and bioaerosols. If so, then you need to consider human health in addition to the potential nuisance effects to neighbours

4. Most waste facilities do not require quantitative dust monitoring, visual monitoring is typically acceptable. Make sure you do not include the need to quantify dust emissions unless absolutely necessary as this can be expensive and time consuming.

5. Your Environmental Management System should contain procedures for incident reporting. Use these documents to self-report instances when significant dust emissions left the site boundary and what was done about the incident. These records can be invaluable if the regulators receive complaints and make investigations.

6. Provide training to all site workers with regard to what action should be taken to minimise dust emissions and what to do in case significant dust emissions occur. Keep training records to evidence this.

7. Maintain your dust control equipment so that it is always in good working order. The regulators will not make allowance for equipment failure if dust has caused nuisance to your neighbours.

8. Receptors - consider if there is a pathway for the dust to reach them. A receptor may be downwind of the site, it may be very close to the site but if there are buildings or trees in between then this will affect the potential for the dust to reach the receptor.

9. If there are significant dust emissions blowing across your site from neighboring sites, then record this as an incident on your site. Take photos, if possible, and record the fact that the dust was not generated on your site. Such records can remove you from regulators investigations.

10. Seek advice. Check out guidance documents M17 and M8 (these are due to be updated and merged some).Having submitted dozens of Dust Management Plans to the regulators we know that what is required to get approval on a Dust Management Plan is often not intuitive or even logical! So do contact us if you need any assistance or advice.

09 April 2021

I have noticed, over the last few years, an increased focus on the subject of dust emissions from waste facilities. Almost without exception, dust is raised as a... Read more

Which Waste Code for Plastic Window Frames : Why does it matter?

Regulation of Plastic Window Frame Recycling

Environmental Permits and Exemptions are necessary for waste recycling facilities to comply with waste regulation. Plastic window frames are defined as a waste material once they are collected for recycling. The treatment of window frames is therefore subject to either control under an Environmental Permit or an Exemption from permitting. The difference in operating under an Environmental Permit or an Exemption is massive. Not only in financial terms but also in on going management and operation of the recycling facility.

Sites that recycle plastic window frames typically do so under a T4 Waste Exemption (preparatory treatment, such as, baling, sorting, shredding). This exemption allows an operator to treat up to 100 tonnes of plastic waste (or 3000 tonnes if within a building) in any seven-day period and store up to 500 tonnes on site. These are significant tonnages which allow a reasonable sized site to operate under the exemption. A much lighter regulatory touch than for many other types of waste recycling activities of this scale.

However, the exemption relies on the fact that the plastic window frame waste is identified as one of the following waste codes 17 02 03, 19 12 04 or 20 01 39.Until recently this has been the case, however, I am seeing instances of the Environment Agency enforcing the identification of waste window frames with the code 17 09 04 or 19 12 12.This is due to the inclusion of other materials such as metal in the window frames, making this a mixed waste!

Since the T4 Exemption does not include for waste coded as 19 12 04 or 19 12 12 sites operating under the T4 will now have to obtain an environmental permit. This represents a massive step-up in terms of the regulation of this waste treatment activity. Not only will this cause a significant cost but may also cause a disruption to the business if the Environment Agency do not allow the activity to continue while the permit is sorted out.

This remains a contentious point since elsewhere in regulatory guidance plastic window frames have been associated with the code 17 02 03 (withdrawn LRW 484).

It appears that the other environmental Regulators (Natural Resource Wales and SEPA) are, for now, not taking the same approach regarding the coding of plastic window frames.

|

Waste materials are assigned a code (List of Waste Regulations 2005) and these codes appear in Environmental Permits and Exemptions. Codes that can be used to describe waste window frames are:

|

What Should I Do?

If you are recycling plastic window frames under a T4 Exemption, then do take advice on how to obtain an Environmental Permit. Make sure you are aware of the potential costs and timescales involved. Have a business continuity plan in place should the Environment Agency revoke your Exemption.

Westbury Environmental Limited can provide advice on all aspects of Environmental Permitting. We have experience of helping many clients throughout the waste industry to obtain permits. We start by explaining the whole process to you, identify the costs and once you have your permit, we continue to help your business to remain compliant. Contact us for more information here.

01 February 2021

Regulation of Plastic Window Frame Recycling

Environmental Permits and Exemptions are necessary for waste recycling facilities to comply wit... Read more

Sampling and Analysis of Trommel Fines

Recently the Environment Agency (EA) released a letter to be sent to all waste operators (in England) who produce Trommel Fines. This letter stressed the importance of correct classification of trommel fines and highlighted the fact that “only when a waste assessment, carried out in accordance with WM3 guidance, shows the waste does not display any hazardous properties, can the non-hazardous mirror waste codes be assigned (19 12 12)”

The need to classify waste in accordance with WM3 guidance is not new and applies to all waste regardless of its LOW code.

Following its national campaign to better understand the chemical composition of trommel fines the EA reported to have found over half the samples breached hazardous waste thresholds. Typically, waste operators have assumed that non-hazardous waste treatment would produce non-hazardous fines and have coded this waste 19 12 12 rather than 19 12 11* (hazardous waste) without undertaking any analysis and assessment.

The EA sign off the letter by stating that they ‘will request to see copies of your waste assessments during future compliance visits’.

In addition to the analysis required to assess hazardous properties and correctly classify the trommel fines, if the fines are to be disposed of to landfill then there are other tests that need to be carried out in relation to landfill waste acceptance criteria. I generally find that operators are more familiar with these landfill requirements but not with waste classification requirements. The Technical Guidance document WM3 provides a detailed and comprehensive account of how waste should be classified.

WM3 requires:

- That the technical goals and objectives are identified.

- That sampling is undertaken to ensure a representative sample is obtained.

- That all compounds that may be present in the waste are analysed for.

- That an assessment is carried out to identify if the waste displays any of the 15 possible hazardous properties.

It is no longer the case that old rules of thumb can be used, such as ‘the metal concentrations add up to less than 2,500mg/kg therefore waste is non-hazardous’.

What Should I Do?

Firstly, do not rush off, grab a sample and send it to the lab asking for a WM3 test and assessment. In many cases this will not result in a robust classification that would pass the scrutiny of the EA. Consider how you will sample the waste and document this (see WM3 appendix D and the sampling form).Talk to the lab/consultant about a suitable suite of determinants that would be appropriate and get a properly trained person to undertake the assessment. When you get the assessment report – make sure you are satisfied with the accuracy of its content.

I am certain that right now that any trommel fines producers are counting the additional costs of these requirements. However, also consider the potential ramifications of not classifying this waste or of misclassification, including increased permit costs, fines, prosecutions etc. You will find a free video resource available on our website that talks about trommel fines in more depth. Click here.

Westbury Environmental Limited have worked with many waste operators over several years to ensure that waste classification requirements are met as efficiently as possible. We work with laboratories and have fully trained haz. waste assessors to ensure a robust assessment is achieved. We also provide training via our webinars. Are you classifying your waste correctly? Are you sure? If you answered "No" to either of these questions, then you are not alone. Join us for our upcoming webinar Your Waste: Is it Hazardous? starting on Tuesday 1st December, to gain an understanding of waste classification and the consequences of getting it wrong. Find out more and register your place here.

13 November 2020

Recently the Environment Agency (EA) released a letter to be sent to all waste operators (in England) who produce Trommel Fines. This letter stressed the importa... Read more

Environmental Protection VS Environmental Regulation

Now you would be forgiven for assuming environmental protection and environmental regulation would be inextricably connected. That the primary objective of environmental regulation was to provide protection to the environment. However, in my work as an environmental consultant over the last 20 years or so, I have seen an increase in instances where the focus of enforcement of regulation appears to have little to no basis in environmental protection. Coupled with increasing penalties for falling foul of environmental regulators, this is an ominous prospect for operators of waste sites.

Don't get me wrong, I wholeheartedly support the regulation of our waste industry and feel that we largely have adequate and effective regulation in place. But, when I repeatedly have to deal with situations between regulators and operators that have little connection to environmental protection and more to do with the correct bit of paper, being in the right place at the right time, it simply boils my blood. Especially when this results in operators being subject to harsh penalties, when no environmental harm is evident or even suspected, compared to blatant waste criminals who have caused obvious environmental harm.

So how can operators protect themselves from such liabilities? It comes down to knowledge and a good amount of documentation.

So, let's deal with knowledge first. Ignorance is never an acceptable excuse. And by the way, it is not the job of the regulator to make you aware of the regulatory requirements for your operations. While they may give you advice, they will take no responsibility if their advice is wrong and then may seek to prosecute you for getting it wrong as a result! Get independent advice from an experienced consultant, put yourself on courses, talk to other operators in the industry, get involved with industry associations and consult guidance documents.

Having the correct documentation is crucially important. This generally starts with the Environmental Permit and goes all the way down to the records you keep that evidence the implementation of procedures on site. Such procedures should form part of your Environmental Management System (EMS) along with risk assessments, emission management plans and other documents.

I often find that, even the most diligent, waste site operators find EMS paperwork a challenge and don’t have a full understanding of what their Environmental Permit allows them to do. These operators are at risk from inadvertently operating unlawfully which could lead to increased permit costs and potential prosecution.

I explore both of these subjects in a webinar series that I am running on 10th and 12th November. This short webinar series will help attendees understand Environmental Permits and what an EMS should look like and how to implement it. To register your place or find out more, click here.

01 September 2020

Now you would be forgiven for assuming environmental protection and environmental regulation would be inextricably connected. That the primary objective of environmental regulation was to pr... Read more

Certainty and Clarity: Getting a Simple Answer

“More important than the quest for certainty, is the quest for clarity”

Francois Gautier

I am sure you will agree that the guidance provided by the Government on the changing COVID19 lockdown measures is far from clear. Furthermore, we can’t be certain about the risk from the virus even if we follow these guidelines. As a business owner, mother, sister and daughter I have had to make decisions about retuning my workforce to the office, having family visits etc. Due to the lack of clarity in the guidance I have felt a degree of uncertainty as to whether I am making the right decisions.

As a consultant, I regularly talk to people in the waste industry about waste regulation. I have recently recognised that my feelings of frustration over the lack of clarity and the uncertainty around the COVID19 guidance is very similar to the feeling that my clients have when navigating their way through guidance on waste regulation. They never quite, despite reading reams of guidance, feel that they fully understand all the potential implications of the regulations and guidance. On one hand you have information overload – pages and pages of text, with links throughout to even more pages, such that you can easily feel that you are being lost down a rabbit hole and maybe missing what you are looking for. On the other hand, you have the feeling that there is nothing in the guidance that fits your specific situation or answers a simple question. Unless you work with these regulations/guidance on a regular basis it is my view that you could easily get to the wrong conclusions/answer and the consequences could be severe.

So, what’s the answer?

Seek professional advice.

There will typically be a cost involved with this so ensure the professional you choose has the necessary experience and credentials. Don’t be afraid to ask.

Get some training.

Several organisations including CIWM, WAMITAB and private companies provide a range of courses on a variety of subjects.

Ask Google / You Tube.

Beware of old posts as this may not reflect the current situation. Of course .gov.uk has all the information but it can feel like eating an elephant. Millions of how-to videos can be found on these platforms however, from my searches, there is little to nothing to help you here regarding waste regulation.

The lack of helpful information in short video format produced specifically for the waste industry is the reason I have recently set up the Academy on the Westbury Environmental Limited website. The Academy contains videos to provide answers to the most common questions that I regularly get asked, along with more detailed training videos on a variety of topics. We also run a number of webinars during which attendees can ask questions. My focus is on increasing the content of The Academy to build this resource. Do get in touch if you are having problems getting answers to your queries, I am sure we can help. Or maybe drop us a line if there is a subject you would like to see covered by our training videos.

13 July 2020

“More important than the quest for certainty, is the quest for clarity”

Francois Gautier

I am sure you will agree that t... Read more

How an EMS can protect Waste Site Operators from the effects of COVID19

No, an Environmental Management System (EMS) cannot act as a vaccine, but a good EMS really could help waste site operators get through these difficult times.

COVID19 has had a global impact, brought cities to a virtual standstill and changed our day to day lives. However, the Env. Agency will still regulate permit holders and act to protect the environment. The Government have deemed waste workers as ‘key workers’ who are essential to keeping public services running so business continues in this sector .

Social distancing requirements and the fact that many Env. Agency officers are working from home, far fewer site visits are being undertaken by the Environment Agency. I’m sure waste site operators won’t see this as a problem! However, many operators are experiencing problems due to the impacts of COVID19. I want to highlight just two of these problems and suggest how implementing a robust EMS could help.

Build up of waste on site due to the inability to process / remove it from site. This could cause a breach of your permit conditions, an increased fire risk, cross contamination of waste etc. The Env. Agency have responded by releasing a Regulatory Position Statement (RPS) that applies to the temporary exceedance of waste storage limits due to COVID19 restrictions. Basically, if you exceed your storage limit and comply with all the requirements of the RPS then the EA will not normally take enforcement action against you. Your EMS documentation will be essential in demonstrating to the Env. Agency that you have complied with the conditions of the RPS.

No ‘Technically Competent Management’ on the site. This may be due to the inability for managers to complete their Continued Competence tests, they may be furloughed, in self isolation or not able to attend the site. As part of the Env. Agency guidance it is stated that in the absence of a TCM “The operator should be able and capable of operating the plant or site through both their EMS and operations training”.

An EMS should reflect the complexity of the waste operation / site. Lower risk activities will have simpler EMS’s than higher risk activities. Gone are the days where an old Working Plan would suffice. All EMS’s should contain a number of documents including Environmental Risk Assessments, Emission Management Plans, drawings, process flow information etc. and procedures. Documented assessments and plans can be difficult, if not impossible to implement. Therefore, the EMS should bring together all the requirements of these documents into procedures. These procedures should be brief and instructional and may be associated with records that are kept to evidence the implementation of the procedure. Records are also required to evidence the training of staff on the procedures. I recently had a case where an operator was given a non-compliance score by the Env. Agency due to not having training records despite having a good EMS.

How we can help.

We can provide you with guidance on the development of your EMS or simply take care of the whole process for you. There is no generic template involved, each EMS is as unique as the sites and operators are.

We can provide training on the implementation of the EMS. Not face to face of course at the moment but as I type, we are creating online content on this very subject. Training which even furloughed staff can benefit from.

Click here to find out more about the Academy, our online resource centre.

08 June 2020

No, an Environmental Management System (EMS) cannot act as a vaccine, but a good EMS really could help waste site operators get through these difficult times.

COVID19 has had a globa... Read more

Cyber Essentials: A badge we are proud to wear

Even as a small consultancy we handle an immense amount of electronic data. Focus has been on the organisation of that data to ensure information can be

readily retrieved. However, more recently we have turned our focus to security.

Following a successful funding application in late 2019, we replaced all our IT equipment. This paved the way for our application for certification

under Cyber Essentials. This Government backed scheme is designed to help you to protect your organisation against a whole range of the most common

cyber attacks.

Despite the pandemic we did not want to delay progress and submitted it just after the lockdown. Of course, we were all working from home by that time.

I was gutted to have our application rejected by the auditor due to temporary changes in our working situation due to COVID19. We turned around

the situation within 48 hours and was awarded the certificate. As such, I think we are the first and may be the only company to have a pandemic

proof Cyber Essentials certificate.

I must mention the superb work from Bespoke Computing Ltd. in Telford who designed, installed and set up our whole IT system, they have provided on-going

support and assisted us with our Cyber Essentials application.

We take our responsibility for the security of our IT system very seriously and are proud to be able to demonstrate this to our clients and suppliers

by proudly wearing our Cyber Essentials badge – in an electronically acceptable way of course.

14 May 2020

Even as a small consultancy we handle an immense amount of electronic data. Focus has been on the organisation of that data to ensure information can be

readily retrieved. However,... Read more

Are you classifying your waste correctly?

By Georgie Watkins

Misclassifying or not classifying your waste can have serious consequences. Without a clear understanding of the waste classification process, waste producers

and operators could find themselves facing the wrath of the Environment Agency on this issue.

Technical Guidance WM3 provides guidance on how to assess and classify waste. Environment Agency officers have recently received in-depth training on this

guidance. As a result, we consider it highly likely that this will result in more waste producers and operators being asked to present evidence that

they have classified their waste correctly. If such evidence is not available it could lead to non-compliance scores on Compliance Audit Reports, higher

annual subsistence fees for permits, fines and prosecutions.

Last year, a small waste operator was prosecuted by the Environment Agency for incorrectly classifying waste that was brought into his waste site. The

waste that they thought was non-hazardous “soils and stones”, turned out to contain a hazardous concentration of asbestos fibres and the waste should

have been classified as “soils and stones containing hazardous substances”. The operator was prosecuted and subject to a £20,000 fine plus costs. These

fines appear to be only increasing as time goes on.

There are several outdated “rules-of-thumb” with regard to classifying waste that are widespread in the waste industry and should not be used. Such as, the waste is non-hazardous if:

- the metals concentrations add up to below 1000mg/kg.

- the metal adds up to less than 2,500mg/kg.

- the waste has failed inert WAC.

Waste can only be classified as “non-hazardous” or “hazardous” if it has been classified in accordance with the Technical Guidance. The use of the term

“Inert” immediately suggests that landfill acceptance criteria has been incorrectly used to classify waste. Hazardous waste assessments must be carried

out using total content analysis data and not using eluate analysis data (landfill WAC tests). To explain this, think of a cup of tea, you have the

tea bag and the water and the resulting tea drink. To classify the waste as hazardous or non-hazardous you need to test the tea bag. Only if it is

going to landfill would you then do a test on the tea drink that results from the tea bag in the water.

You may be thinking that only waste that is coded with mirror entry codes needs to be classified, for example waste from a waste treatment process can

be coded as 19 12 12 non-hazardous and 19 12 11* hazardous. However, all waste needs to be classified to determine its hazardous properties. So, an

absolute non-hazardous coded waste such as 20 02 02 (soil and stones from parks and gardens) could have hazardous properties and these would need to

be identified on the Waste Transfer Note. Likewise, you still must assess an absolute hazardous coded waste to be able to identify its hazardous properties.

Not all waste classification assessments are made equal! There is a level of competency required to produce a robust classification. If you have any doubt, come along to our one-day seminar “Your Waste: Is it Hazardous?” to be held in London and Norwich this year where we will talk you through the classification process. Even if you do not do classifications yourself, we will teach you how to tell a robust report from a poor one.

11 May 2020

By Georgie Watkins

Misclassifying or not classifying your waste can have serious consequences. Without a clear understanding of the waste classification process, waste producers and o... Read more

Regulation of soil – clear as mud

By Tracey Westbury

The most common questions that I get asked are those surrounding soil. Considerable confusion exists over; when it is defined as a waste or not, it’s classification and waste coding, what to test for and what the results mean, the lawfulness of its reuse on the site of origin or on other sites, its use in landscaping, construction and restoration projects, when it has been recovered or when it has been disposed of, this list could go on.

Soil is a massive resource. It is reported that 58.7 million tonnes of waste soil were generated in the UK in 2016.This figure does not include ‘mineral waste’ of which 81.1 million tonnes was generated. It is not surprising then that there are several prosecutions each year by the Environment Agency in relation to soil. In addition to prosecution, there is the threat of fines from HMRC for avoidance of landfill tax for unlawful deposits of soil. At a fine of nearly £90 per tonne this far exceeds the landfill tax that would otherwise have been levied on the waste soil had it actually been disposed of to landfill.

Even with the best intentions, operators/developers can find themselves on the wrong side of the law. Without a clear understanding of the regulatory regime, code of practice and technical guidance the chances of getting it all correct are slim to none, unless a competent advisor is used. A competent adviser should be able to describe the options available to ensure that the movement / treatment / deposit of the soil is lawful. It is appropriate in this case that a ‘little bit of knowledge is a dangerous thing’. I often see, for example, Site Investigation reports that provide a little ‘helpful’ advice on complying with waste regulation. Often this is so inaccurate / misleading that it would leave the operator open to prosecution should this advice be taken.

I feel the need to mention recycled soil. By that I mean soil that has been through a mechanical treatment process, typically screening. Such treatment separates larger aggregate fractions from smaller particles considered to be soil. The larger aggregate fraction can reach ‘end of a status’ in accordance with the WRAP Quality Protocol for Aggregates from Inert Waste. However, there is presently no way to get the soil fraction out of the definition of waste. No matter if it complies with BS3882 or not, this is only a quality standard to ensure that the soil can support plant growth and has no bearing whatsoever on the definition of material as waste or not.

Useful reading includes the AGS Guidance on Waste Classification for Soils – A Practitioners Guide, the CL:AIRE Definition of Waste: Development Industry Code of Practice and webpages on the Environment Agency website.

Alternatively, you could attend our one-day seminar focussing on this subject being held in 2020 in Norwich, London and Telford.

Click here to book your tickets

06 January 2020

By Tracey Westbury

The most common questions that I get asked are those surrounding soil. Considerable confusion exists over; when it is defined as a waste or not, it’s clas... Read more

)

)

)

)

)

)

)

)

)

)

)

)